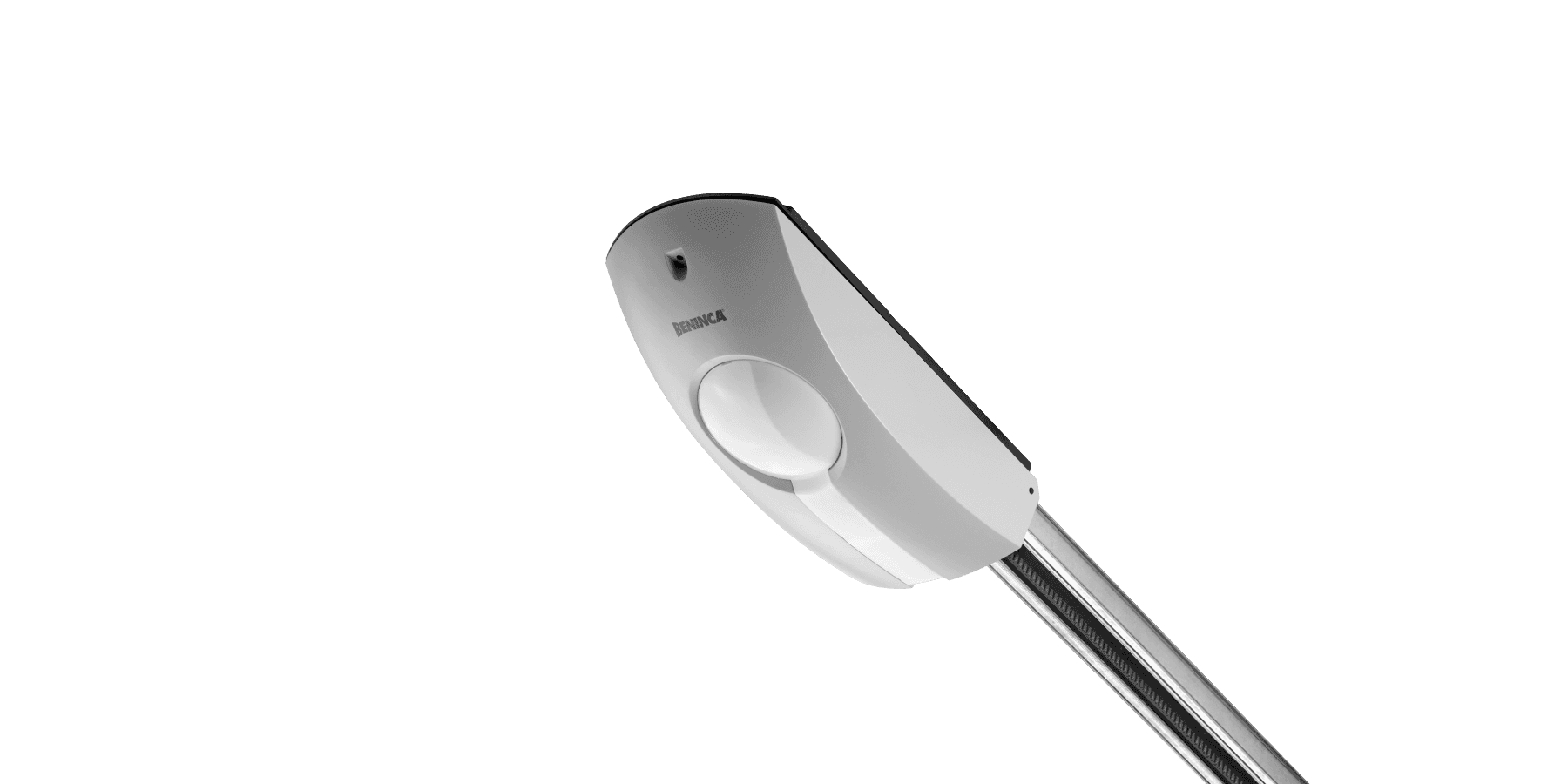

Geared motor JM.4ESA

Residential use

Commercial use

Sectional garage doors

24 Vdc

Up to 22 ㎡

Integrated device that guarantees maximum precision during the automation manoeuvring steps

Intelligent power control system that allows obtaining dynamic data through a precise calculation of the thrust. The system is able to locate any critical points and adjust the torque accordingly in relation to actual requirements and according to measured performance

64 transmitters storable inside the receiver

JM.4ESA

24 Vdc | intensive use

24 Vdc gear motor for intensive use, with integrated control unit and encoder | Adjustable stroke with one mechanical stop included in the belt rails and two in the chain rails | Anti-crushing system with amperometric obstacle detection | Operation guaranteed even in the event of a power supply failure through batteries that integrate perfectly into the motor | Evolved electronics with display and energy saving courtesy light | The encoder guarantees maximum safety and precision while the gate is moving | Quick hooking system for connecting the arm to the door plate

Rail not included

| Power supply | 230 Vac (50-60Hz) |

| Motor supply | 24 Vdc |

| Max absorbed current | 1,5 A |

| Thrust | 1200 N |

| Opening speed | 8.9 m/min |

| Duty cycle | intensive use |

| Protection level | IP40 |

| Built-in control unit | |

| Integrated receiver | |

| Encoder | |

| Limit switch | electronic with encoder |

| Operating temperature | -20°C /+50°C |

| Door surface area | 22 ㎡/max |

| Weight | 6.6 kg |

| N. motors per pallet | 50 |

CP.J4ESA

APPLICATION

1 actuator series JM.3ESA, JM.4ESA

CONTROL UNIT POWER SUPPLY

230 Vac - 50/60 Hz

MOTORS POWER SUPPLY

24 Vdc / 8.5 A

MAIN FUNCTIONS

Integrated LCD display | Integrated 433.92 MHz 64-code radio receiver with 3 encoding systems (Advanced Rolling Code, Rolling Code, Fixed Code) | Integrated ESA SYSTEM for energy savings | Fixed terminal boards | Automatic and semi-automatic logic | Step by step, open, close, stop and photocell inputs | Input for N.C or 8K2 sensitive edge | Output for configuration as gate open indicator, service light, second radio channel or area light | Output for connecting the flashing light | Photocell testing | Autosetting of operating parameters | Electronic torque adjustment with automatic calculation for each point in the stroke (STC SYSTEM) | Anti-crushing safety thanks to amperometric detection and encoder management | Possibility of setting a slower starting speed for 2 seconds (SOFT START) | Adjustable slow-downs | Advantouch system to configure parameters and manage radio transmitters | Number of maneuvers | Programming access password | Maintenance warning