Geared motor VN.M20 ESW

VN.M20 ESW

230 Vac

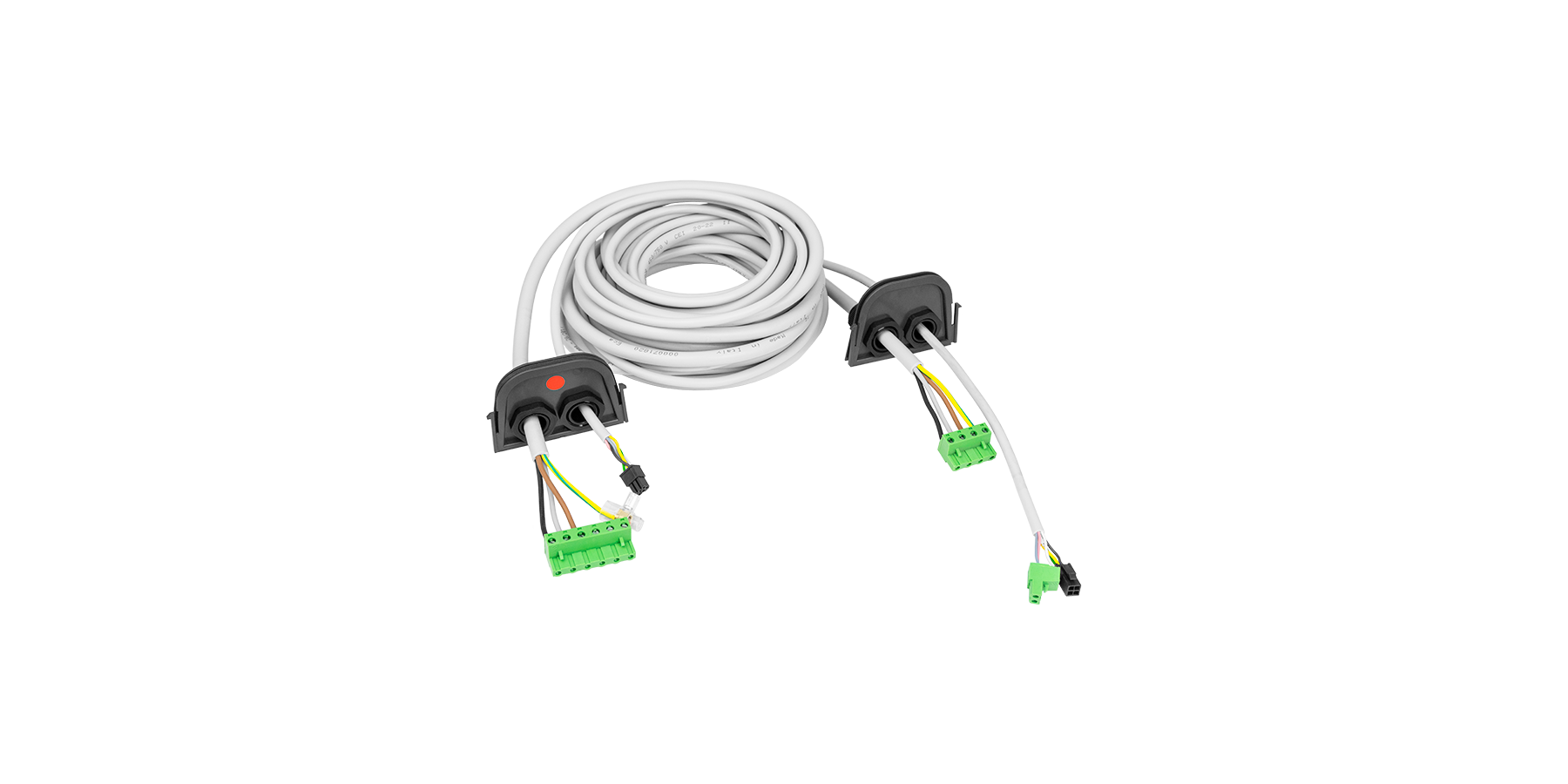

230 Vac gear motor with encoder, manual chain movement and 1/20 reduction rates | Plastic box that makes wiring the motor easier, thanks to the position of the front clip connector and the possibility of reaching three different positions with the wiring | Equipped with absolute encoder that permits the regulation of the positions of the opening and closing limit switches on the door directly from the control unit | Quick plug-in connection for quick and easy installation | Two accessories are available for chain drives with gear speed reduction rates 1:1 (off-axis motor installation) or 1:1.8 (torque or speed multipliers) | Maximum safety guaranteed during rapid release phases, thanks to a micro-switch that cuts the power supply to the motor | Oil lubricated reductions with hardened steel screw and bronze gears guarantee high performance, maximum reliability and silent operation | Also available in kit version with motor, 5 m cable and THINKY control unit

| Power supply | 230 Vac (50-60Hz) |

| Motor supply | 230 Vac |

| Max absorbed current | 3.3 A |

| Max torque | 130 Nm |

| Maximum output rotations | 18 |

| Output speed | 24 r.p.m. |

| Shaft hole | 1” (25.4 mm) |

| Limit switch reduction ratio | 1/20 |

| Duty cycle | 30% |

| Protection level | IP40 |

| Built-in control unit | |

| Integrated receiver | |

| Encoder | |

| Operating temperature | -20°C /+50°C |

| Lubrication | OIL |

| Door surface area | 35 ㎡/max |

| Weight | 15.5 kg |

| N. motors per pallet | 24 |

THINKY

APPLICATION

1 actuator for sectional doors and rolling doors, folding doors with more than two sections, unbalanced shutters and industrial sliding gates

CONTROL UNIT POWER SUPPLY

230 Vac single-phase or 400 Vac three-phase

MOTORS POWER SUPPLY

230 Vac / 800 W or 400 Vac / 2200 W

MAIN FUNCTIONS

Integrated LCD display | Integrated 433.92 MHz 64-code radio receiver with ARC and predesigned for plug-in radio receiver | Predesigned for connection to absolute encoder and quick wiring (VN “ESW” motors) | Autosetting of operating parameters with motors equipped with absolute encoder (VN “ESW” motors) | Removable terminal boards | Automatic, semi-automatic and deadman’s logic | Motor limit switch inputs | Open, close, step by step, pedestrian and stop inputs | Inputs for 4 pairs of photocells (configurable as active in opening-closing or in closing phases) and equipped with PHOTO TEST logic | Input for N.C or 8K2 sensitive edge | Input for safety sensor | Output configurable as gate open indicator, second radio channel, service light and area light | Output configurable as gate open indicator or photocell testing output | Output for connecting flashing light | Protection against phase failure and exceeding motor current threshold | Advantouch system to configure parameters and manage radio transmitters | Number of maneuvers | Programming access password | Maintenance warning