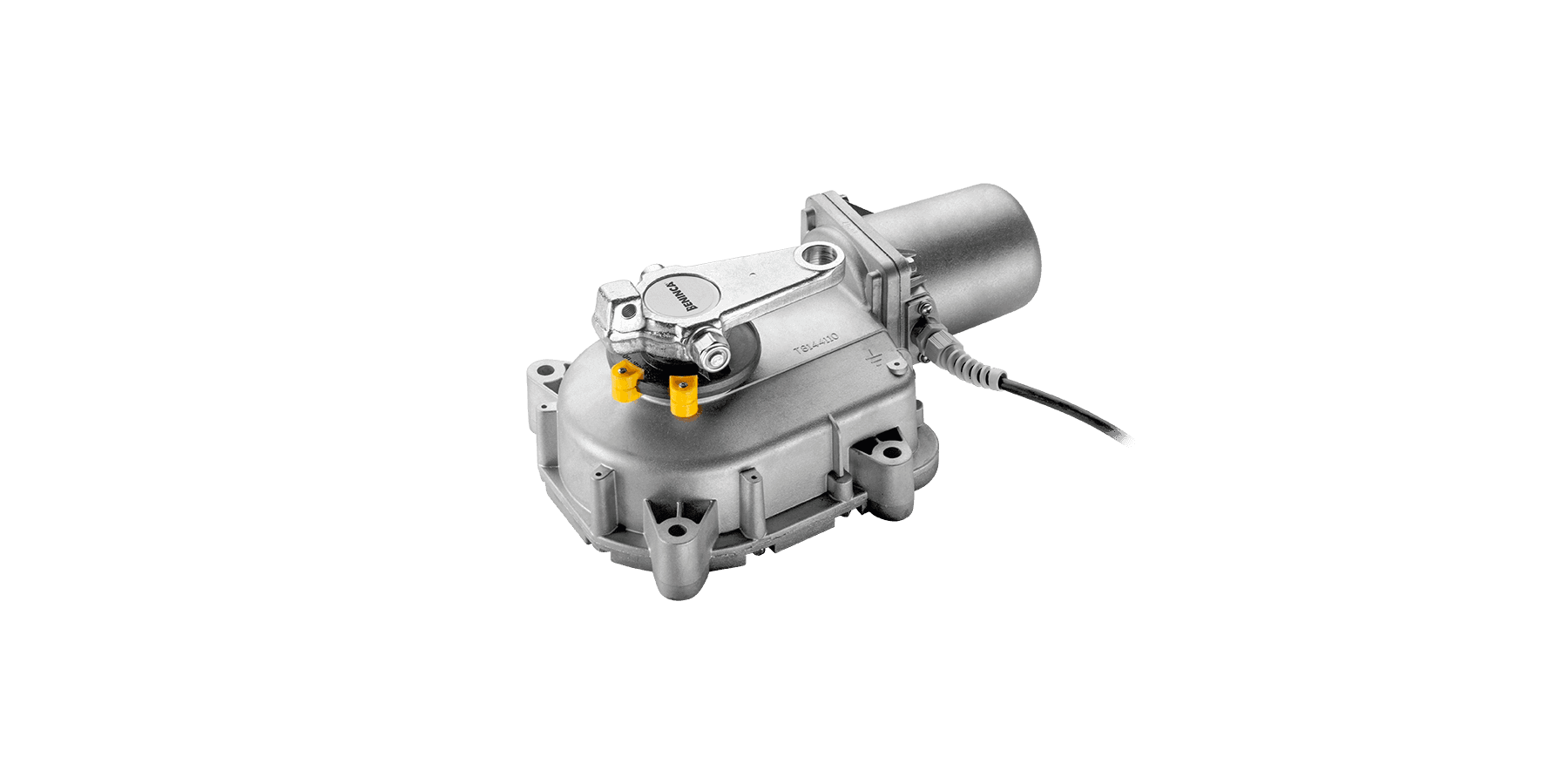

Geared motor DU.IT24NVE

24 Vdc

Up to 3.5 m per door leaf

Integrated device that guarantees maximum precision during the automation manoeuvring steps

Integrated device that guarantees maximum precision during the automation manoeuvring steps

Designed to manage the control unit using the BeUP app and pro.UP accessory which, by recreating the control unit menu, makes it possible to adjust parameters and logic, read error messages and update the firmware. It is possible to perform remote diagnostics, check the status of the gate and send commands

DU.IT24NVE

24 Vdc | intensive use

Irreversible 24 Vdc electromechanical geared motor for intensive use, equipped with IP68 encoder | The encoder device ensures maximum safety and precision in the gate moving phases | Amperometric sensor obstacle detection system to prevent crushing | Optional battery powered operation | Full metal mechanics and built-in mechanical stop

Cam disk included

| Motor supply | 24 Vdc |

| Max absorbed current | 11 A |

| Torque | 280 Nm |

| Opening time | 15” |

| Duty cycle | intensive use |

| Protection level | IP67 |

| Built-in control unit | |

| Encoder | |

| Operating temperature | -20°C /+50°C |

| Lubrication | GREASE |

| Leaf max dimension | 3.5 m |

| Weight | 10 kg |

| N. motors per pallet | 44 |

| DU.ITIX weight | 8.1 kg |

| DU.ITCF weight | 9.6 kg |

| N. of foundation boxes per pallet | 32 |

BRAINY24

APPLICATION

1 or 2 actuators for swing gates, opposed sliding gates, and industrial folding doors with a maximum of 2 sections

CONTROL UNIT POWER SUPPLY

230 Vac - 50/60 Hz

MOTORS POWER SUPPLY

24 Vdc / 120 W + 120 W

MAIN FUNCTIONS

Integrated LCD display | Integrated 433.92 MHz 64-code receiver with 3 encoding systems (Advanced Rolling Code, Rolling Code, Fixed Code) | Removable terminal boards | Separate limit switch inputs for each motor | Open, close, and pedestrian inputs | Photocell inputs in opening-closing and in closing phases | Input for N.C. or 8K2 sensitive edge | Output for electric lock 12 Vdc | Output for configuration as gate open indicator, service light, second radio channel and photocell testing | Output for connecting flashing light | Autosetting of operating parameters | Separate electronic torque adjustment for each motor | Anti-crushing safety through amperometric detection and encoder management | Separate adjustable slowdowns for each motor in opening and closing phases | Advantouch system to configure parameters and manage radio transmitters | Number of maneuvers | Programming access password | Maintenance warning

BRAINY24 PLUS

APPLICATION

1 or 2 actuators for swing gates, opposed sliding gates, and industrial folding doors with a maximum of 2 sections

CONTROL UNIT POWER SUPPLY

115 or 230 Vac (selectable) 50/60Hz

MOTORS POWER SUPPLY

24 Vdc / 240 W + 240 W

MAIN FUNCTIONS

Integrated LCD display | Integrated radio receiver 433.92 MHz 64 codes and 3 encoding systems (Advanced Rolling Code, Rolling Code, Fixed Code | Removable terminal boards | Separate limit switch inputs for each motor | Open, close, step-by-step and pedestrian inputs | Separate opening-closing and closing photocell inputs | Stop input | Input for N.C. or 8K2 sensitive edge | Encoder Input for 24 Vdc hydraulic motors | Output for 12 Vdc electric lock | 2 outputs configurable as open gate indicator, second radio channel, courtesy light, zone light or photocell testing, flashing light, open gate alarm, NC input alarm | Output for connecting flashing light | Autoset of operating parameters | Separate electronic torque adjustment for each motor | Separate electronic speed adjustment for each motor | Anti-crushing safety through amperometric detection and encoder management | Separate slowdowns for each motor in opening and closing phases | Set up for connection to KNX systems via X.BE card (optional) | Designed for managing, configuring, diagnosing and updating firmware through the BeUP app, using the PRO.UP accessory | Advantouch system to configure parameters and manage radio transmitters | Number of manoeuvres | Programming access password | Maintenance warning | Built-in battery charger