Geared motor SAM.24 PLUS

SAM.24 PLUS

24 Vdc | intensive use

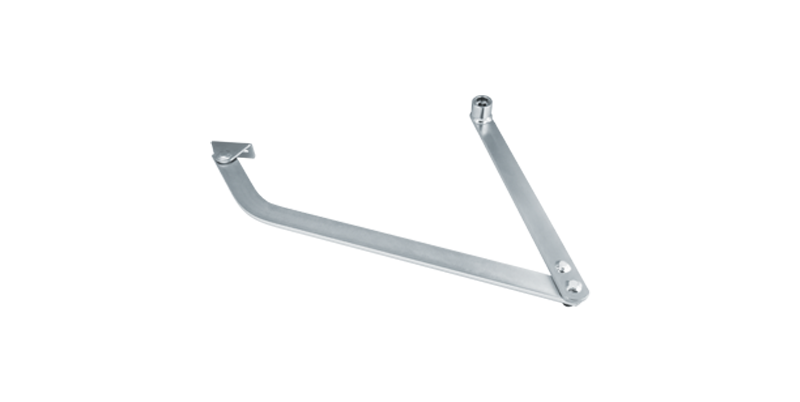

24 Vdc electromechanical operator for intensive use | Ideal for swing gates with large columns and leaf hinges up to 350 mm deep (just 170 mm wide) | The encoder guarantees maximum safety and precision while the gate is moving | Sturdy arm fitted with a closing lock that helps define the limit switch position during installation | The grooved motor shaft ensures maximum stability and resistance | Motor fixing bracket fitted with cable gland | Operation guaranteed even in the event of a power supply failure through batteries that integrate perfectly into the motor | Amperometric sensor obstacle detection system to prevent crushing | Option of adjustable flush release that allows opening from the outside in the event of a power supply failure

Arm not included

| Use | commercial |

| Motor supply | 24 Vdc |

| Max absorbed current | 5.5 A |

| Torque | 240 Nm |

| Opening time | 16” (including slowdown) |

| Duty cycle | intensive use |

| Protection level | IP44 |

| Built-in control unit | |

| Encoder | |

| Mechanical stop in opening | adjustable |

| Mechanical stop for closing | optional |

| Operating temperature | -20°C /+50°C |

| Lubrication | GREASE |

| Leaf max dimension | 2.5 m |

| Weight | 6 kg |

| N. motors per pallet | 45 |

| Kit weight | 20 kg |

| N. kits per pallet | 15 |

BRAINY24

APPLICATION

1 or 2 actuators for swing gates, opposed sliding gates, and industrial folding doors with a maximum of 2 sections

CONTROL UNIT POWER SUPPLY

230 Vac - 50/60 Hz

MOTORS POWER SUPPLY

24 Vdc / 120 W + 120 W

MAIN FUNCTIONS

Integrated LCD display | Integrated 433.92 MHz 64-code receiver with 3 encoding systems (Advanced Rolling Code, Rolling Code, Fixed Code) | Removable terminal boards | Separate limit switch inputs for each motor | Open, close, and pedestrian inputs | Photocell inputs in opening-closing and in closing phases | Input for N.C. or 8K2 sensitive edge | Output for electric lock 12 Vdc | Output for configuration as gate open indicator, service light, second radio channel and photocell testing | Output for connecting flashing light | Autosetting of operating parameters | Separate electronic torque adjustment for each motor | Anti-crushing safety through amperometric detection and encoder management | Separate adjustable slowdowns for each motor in opening and closing phases | Advantouch system to configure parameters and manage radio transmitters | Number of maneuvers | Programming access password | Maintenance warning

BRAINY24 PLUS

APPLICATION

1 or 2 actuators for swing gates, opposed sliding gates, and industrial folding doors with a maximum of 2 sections

CONTROL UNIT POWER SUPPLY

115 or 230 Vac (selectable) 50/60Hz

MOTORS POWER SUPPLY

24 Vdc / 240 W + 240 W

MAIN FUNCTIONS

Integrated LCD display | Integrated radio receiver 433.92 MHz 64 codes and 3 encoding systems (Advanced Rolling Code, Rolling Code, Fixed Code | Removable terminal boards | Separate limit switch inputs for each motor | Open, close, step-by-step and pedestrian inputs | Separate opening-closing and closing photocell inputs | Stop input | Input for N.C. or 8K2 sensitive edge | Encoder Input for 24 Vdc hydraulic motors | Output for 12 Vdc electric lock | 2 outputs configurable as open gate indicator, second radio channel, courtesy light, zone light or photocell testing, flashing light, open gate alarm, NC input alarm | Output for connecting flashing light | Autoset of operating parameters | Separate electronic torque adjustment for each motor | Separate electronic speed adjustment for each motor | Anti-crushing safety through amperometric detection and encoder management | Separate slowdowns for each motor in opening and closing phases | Set up for connection to KNX systems via X.BE card (optional) | Designed for managing, configuring, diagnosing and updating firmware through the BeUP app, using the PRO.UP accessory | Advantouch system to configure parameters and manage radio transmitters | Number of manoeuvres | Programming access password | Maintenance warning | Built-in battery charger

TRUST24

APPLICATION

1 or 2 actuators for swing gates

CONTROL UNIT POWER SUPPLY

100 ÷ 250 Vac - 50/60 Hz

MOTORS POWER SUPPLY

24 Vdc / 130 W + 130 W

MAIN FUNCTIONS

Integrated LCD display | Integrated radio receiver 433.92 MHz 512 codes with ARC coding | Removable terminal boards | Separate limit switch inputs for each motor | Automatic, semi-automatic and Deadman logic | Separate encoder inputs for each motor | Open, close, step-by-step and pedestrian inputs | Input for programmable photocell active in opening-closing and photocell active only in closing | Input for N.C. or 8k2 sensitive edge | Output for electric lock 12/24 Vdc | Two outputs configurable as open gate signal light, courtesy light, zone light, second radio channel, photocell testing, flashing light, alarm contact | Autoset operating parameters | Separate electronic torque adjustment for each motor| Anti-crushing safety through amperometric detection and encoder management | Electronic torque adjustment with automatic calculation for each point of the stroke (STC SYSTEM) | Separate adjustable slowdowns for each motor | Possibility of encoder- or time-based operation (managed through virtual encoder) even independently between the two motors | Built-in energy saving system ESA+ | Set up for connection to KNX systems via X.BE card (optional) | Designed for managing, configuring, diagnosing and updating firmware through the BeUP app, using the PRO.UP accessory | Advantouch system to configure parameters and manage radio transmitters | Number of manoeuvres | Programming access password | Maintenance warning | Built-in battery charger | Standby power consumption complies with European regulation (EU) 2023/826